Walgreens is experimenting with a new store format, which made its debut earlier this year. A few folks from our team recently visited the newly redesigned Walgreens in the South Loop area of Chicago. The experimental new format is a move in the direction of hybrid retail, but we suspect it’ll take several more iterations of this new concept before Walgreens gets it right.

RETAIL VOICES: Curtis Acosta

Curtis Acosta – who coincidentally celebrates his 5-year anniversary of joining OnQ this March – offers a glimpse into the prototyping process in this latest installment of Retail Voices. Unlike many of his colleagues, he spent much of his career outside the retail industry before coming to OnQ.

Tell me a little about your background, and how you wound up at OnQ.

I spent 25 years in the defense and aerospace industries before finding my way to OnQ. During that time, I worked with some of the biggest names in the business, including Boeing, BAE Systems and Lockheed designing and fabricating composite parts for defense missile programs as well as combat vehicle and body armor systems. It was highly classified work that to this day I still can’t talk about publicly.

Coming to OnQ after two-and-a-half decades in the pubic sector seems like an abrupt change of course in your career. How and why did you make the switch?

In many ways, my work in defense and aerospace was the perfect training ground for the work I’m doing at OnQ. Working on classified projects in the public sector is highly regulated and structured. To be successful in that environment, I learned quickly how to operate under constant scrutiny and structure. I was accountable for making sure my team of fabricators delivered as expected every time. After a very successful 25 years in the public sector, I felt it was time to explore opportunities in the private sector.

I can see why you chose the private sector for the next phase of your career. But why OnQ?

Throughout the interview process, the workplace culture was what first drew me to the job. I could tell people here genuinely enjoyed working together – sort of a “work hard and play hard” vibe that was unlike anything I experienced in my previous jobs. That change was refreshing. But what ultimately sold me on the job was talking with Paul, the CEO. He has a very entrepreneurial mindset, and he made it clear that I would have the creative freedom to take the skills I honed over the past 2+ decades and apply them in entirely new ways, in a brand-new industry. From that point on, I was sold on the job.

So tell me a little more about your role at OnQ.

I’m the senior product developer. I run the protoshop, which is where all the prototyping takes place. I get involved once the client signs-off on the final design. I take conceptual and technical drawings and bring those to life. It’s exciting because the prototypes I get to create are the first physi

Having been at OnQ for five years now, has your view of the retail industry changed at all?

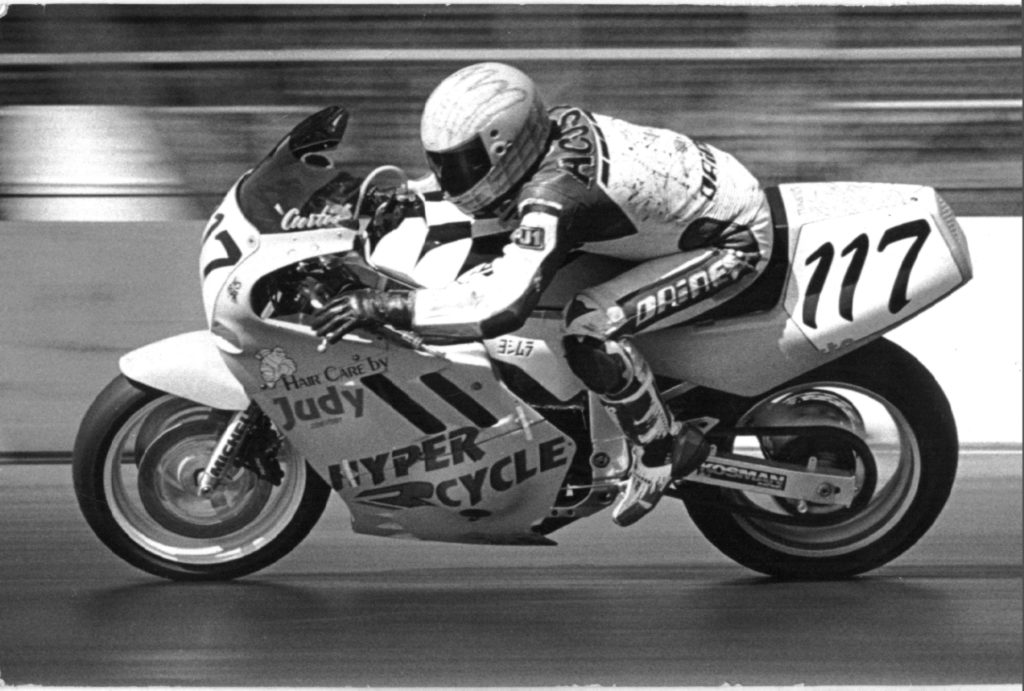

Well, technically I started my career in retail selling motorcycles (did I mention that I also tested and raced motorcycles professionally?). So I’ve seen the retail industry from multiple perspectives. But over the past five years, what’s been most interesting is getting a behind-the-scenes look at how some of the biggest tech companies in the world address the retail space. It’s a really competitive market, and I love that we get to play an important role in how those companies present themselves at retail. It’s so gratifying to walk into a store and see a display that we helped design. In fact, my kids and I have a running challenge to each other to snap pics of OnQ displays we spot while we’re shopping…and we take a lot of those pics!

Wait, you tested and raced motorcycles?

That’s right. My dad was a well-k